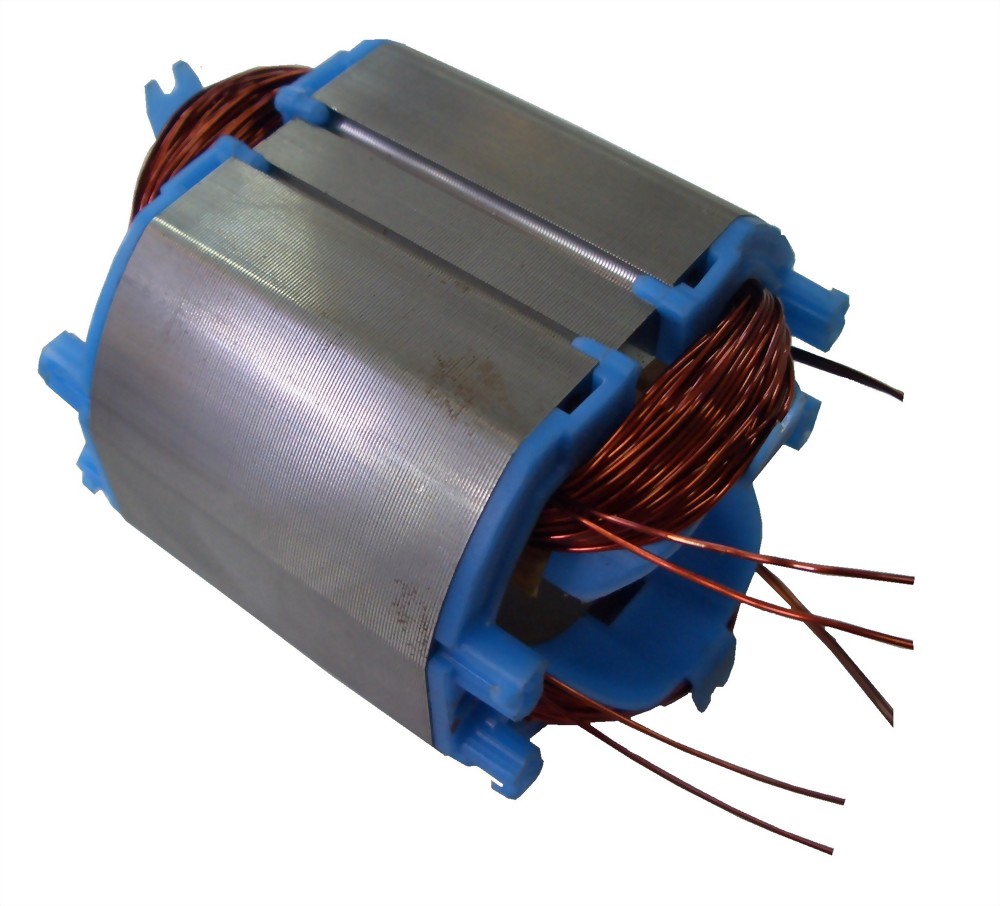

◾Applicable to automatic coil winding for various two poles motors

stators.

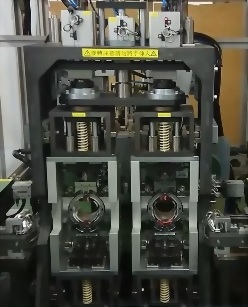

◾This model based on Dual-axes independent control, it is able to set

independent winding parameter, also synchronous to run winding for different

specification of stators, increases applicable flexibility of machine.

◾The design of wire winding mold can be applied automatically and

rapidly, to replace manual die change, modular molds and dies design, it is

able to make fast positioning, and with high repetitive precision, to reduce

time required for mold die changes tremendously, enhances production

efficiency.

◾When change winding for the same stator coil with or without end

insulator, only part of the dies should be replaced.

◾Dies can be shared for this series. The same set of dies may be

changed for different stacked heights to reduce the cost of mold development

tremendously.

◾The analog tension output control system provides tension for the

stator on each coil winding stages and increases the quality level hugely, it

is also optional for servo tension output control, provides more accurate

tension control.

◾With automatic wire cutting mechanism, when stator winding has

finished, capable of cutting copper wire end automatically and clamp it, good

for collection of finished product.

◾Based on Japanese PLC controller with 10" touch panel promptly

to display various operation statuses and running monitoring function.

◾It is able to equip with remote monitoring module to do remote

program monitoring safeguard.

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice。