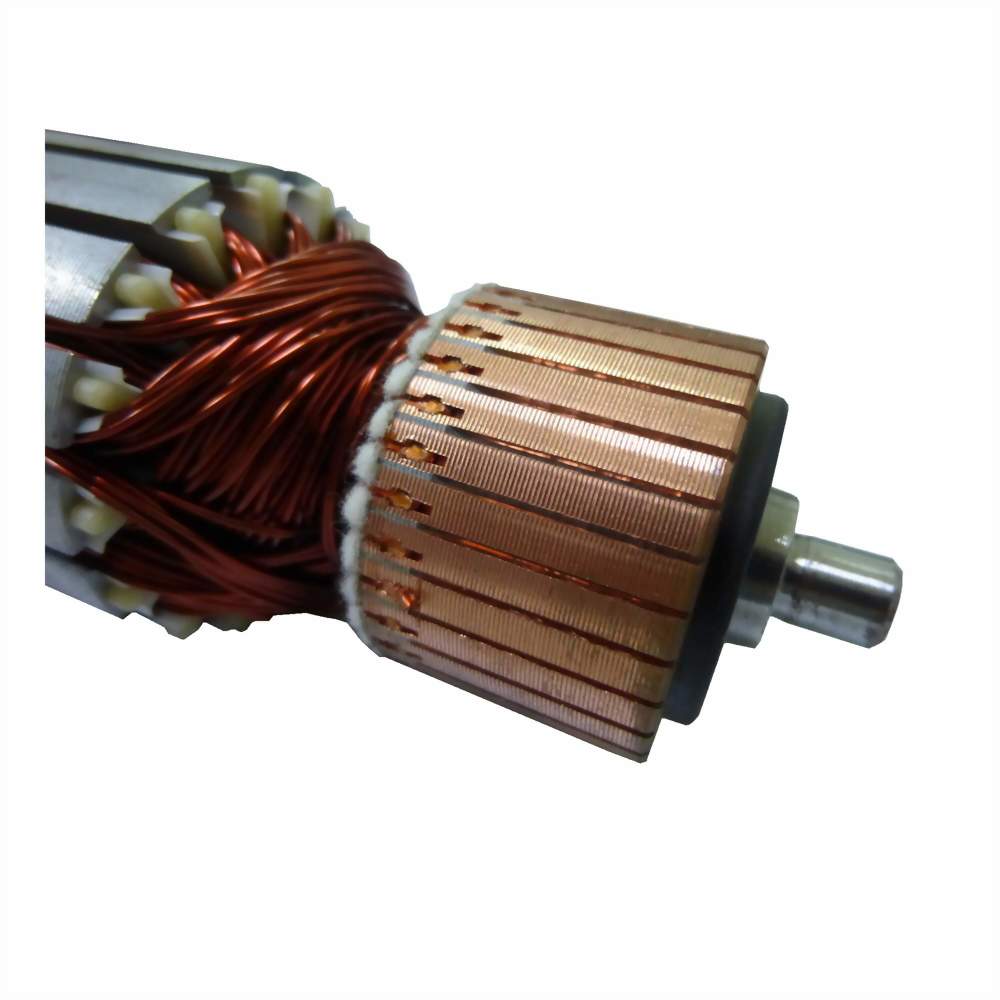

◾Applicable for all kind of brush motor, DC and series hook type armature automatic winding machine.

◾This product can be used for grooved (no hook) type commutator armature. Automatic winding, riveting and trimming can be done in one time. It is widely used in rotors for AC and DC carbon brush motors.

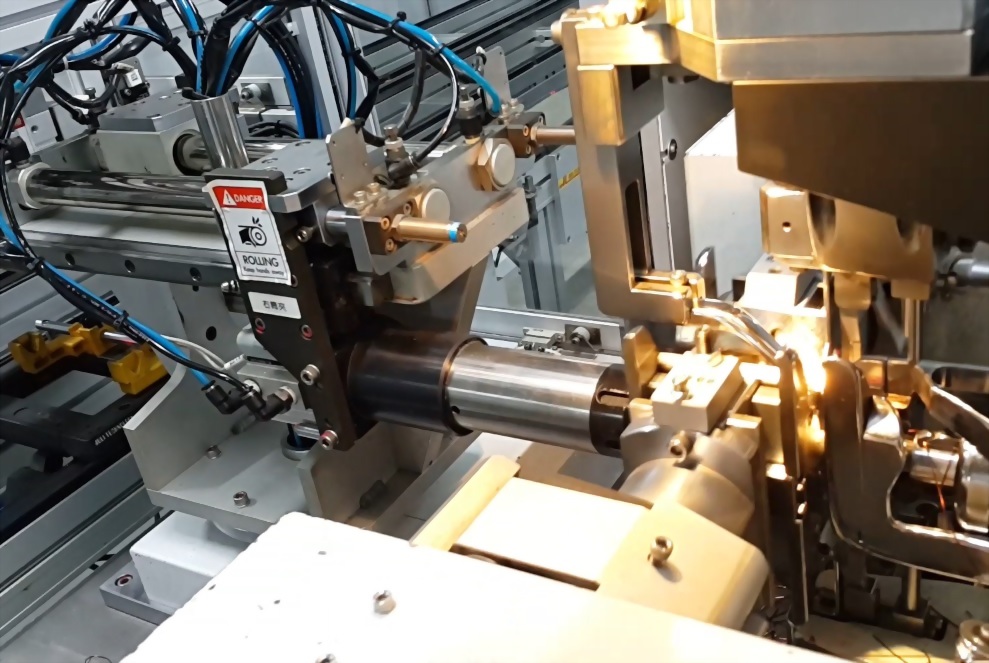

◾Assemble with independent AC servo motor on each flyer for high speed and accurate winding.

◾Switch angles by AC servo motor controller. Accuracy can reach 0.01 degree.

◾Provide a 360-degree wire clamping mechanism motion design and equipped with rotor reversing displacement mechanism so that the tie-line angle can reach at any angle within 360 degree.

◾Wire binding adopts continuous riveting type without thread end, which can effectively improve nail wire quality and enameled wire utilization rate.

◾Modular molding design can be rapidly position and high repetition accuracy which reduce tooling changing time tremendously.

◾Tension system is adopting high sensitive servo tension controller. It can produce several tension controls when winding which optimize tension adjustment performance in each winding operation stage.

◾The control system adopts Japanese PLC with 10” touch screen interface which can display various operation information and monitoring operation in real time.

◾ This product can be connected with a robotic arm and a conveyor belt to achieve fully automatic production line.

◾ This product can be assembled with remote monitoring module for remote program monitoring and maintenance.

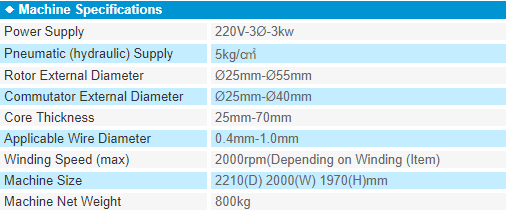

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice.