◾Applicable for all kind of brush motor, DC and series hook type armature automatic winding machine.

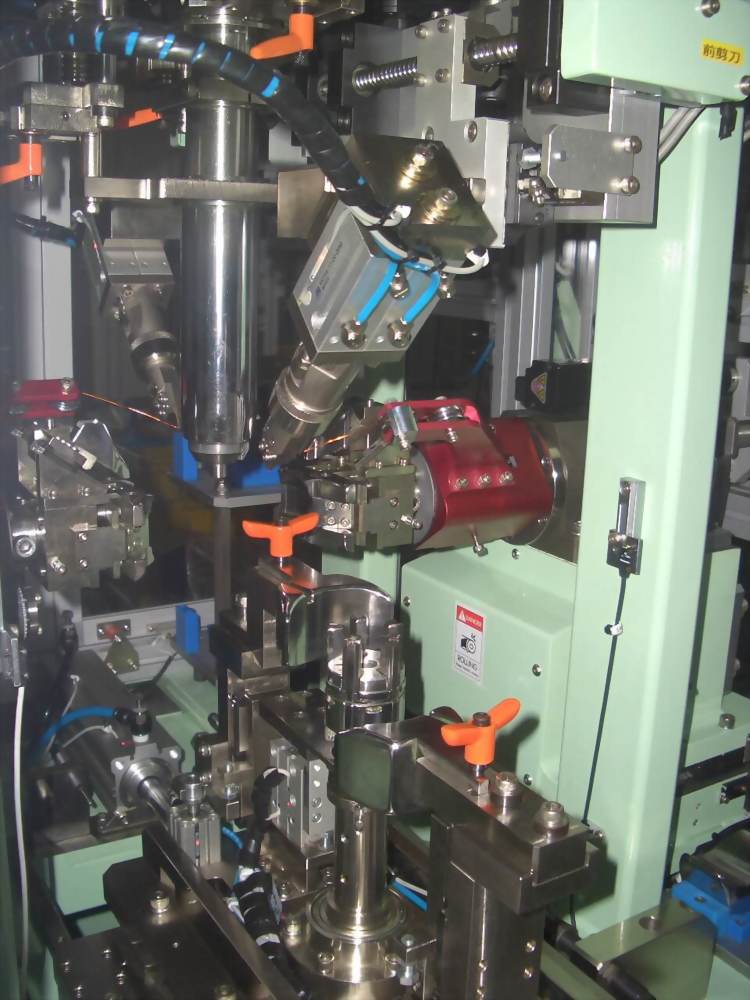

◾Using 14 axis independent AC servo motor. Memorize parameters on each mechanism and largely reduce changing time.

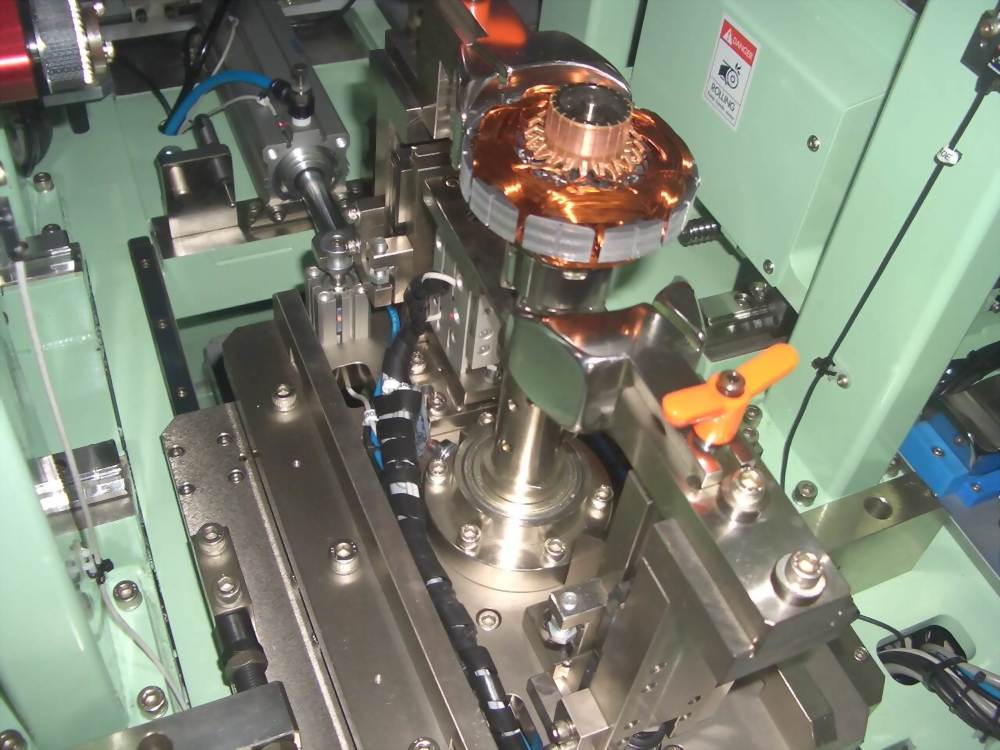

◾ Assemble with independent AC servo motor on each flyer for high speed and accurate winding.

◾ Switch angles by AC servo motor controller. Accuracy can reach 0.01 degree. Various hooking modes can be set at any angle within 360 degree according to the rotor characteristics.

◾ X and Z axis on automatic wire cutting system are driven by two independent AC servo motor and equip with patented wireless debris-free cutter for quick cutting and no waste on cooper wire.

◾ Automatic hook guidance system assemble with two independent AC servo motor can assure satiability while operate under harsh condition and largely reduce equipment action time.

◾ Winding tooling opening/closing and arranging system driven by two independent AC servo motor. Being able to set winding tooling depth of each slot independently. Largely improve winding type and winding volume ratio and largely reduce equipment operation time.

◾ The thread end pressing system, driven by AC servo motor. Suppress the copper wire in the first thread hook which can prevent the thread end loosen at high speed rotation and effectively restrain the length of the first thread.

◾ This product can be equipped with hand-wheel dynamic simulation system. This will largely improve operator’s safety and much more convenience to operating.

◾ Modular molding design can be positioned promptly and high accuracy in repetition. Greatly reduce mold changing time.

◾ Tension system is adopting high sensitive servo tension controller. It can produce several tension controls when winding which optimize tension adjustment performance in each winding operation stage.

◾ The control system adopts Japanese PLC with 10” touch screen interface which can display various operation information and monitoring operation in real time.

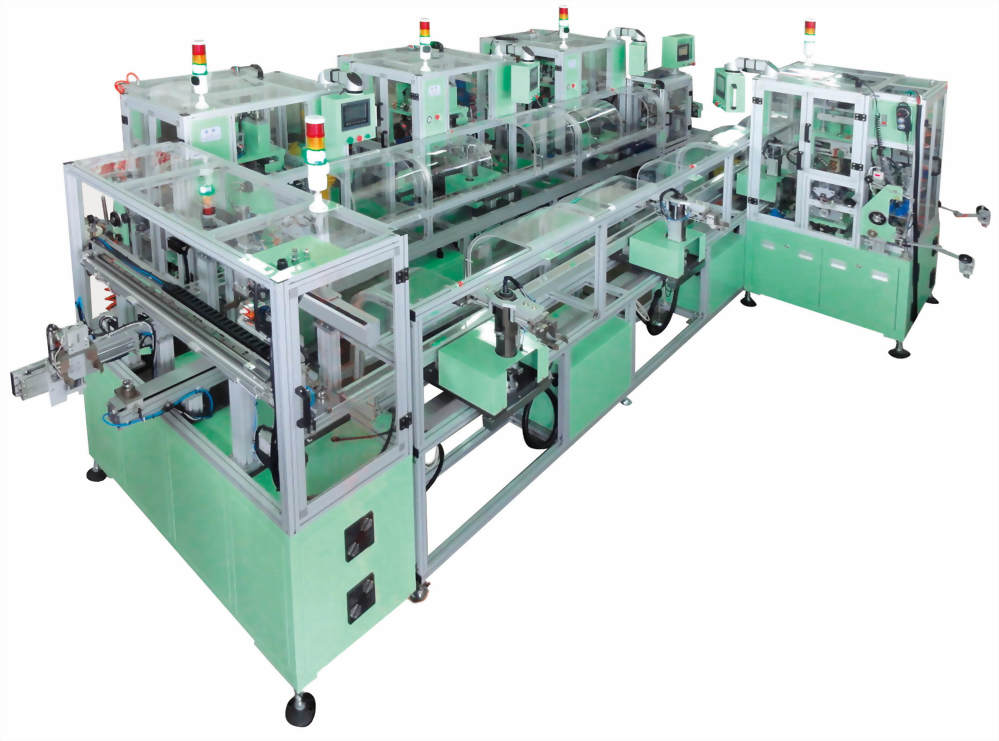

◾ This product can be connected with a robotic arm and a conveyor belt to achieve fully automatic production line.

◾ This product can be assembled with remote monitoring module for remote program monitoring and maintenance.

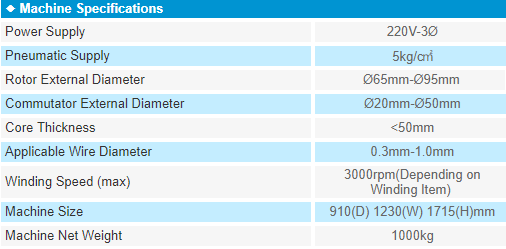

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice.