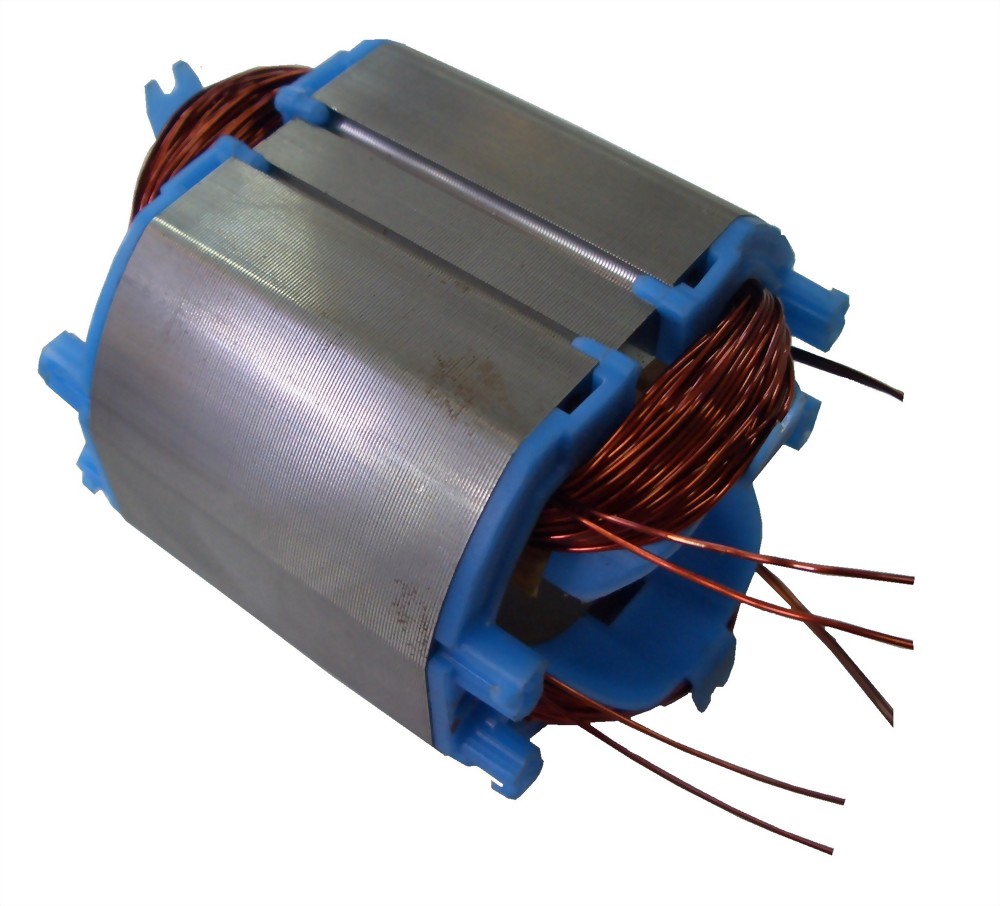

◾Applicable to automatic winding of hook-type armatures for various

carbon brush, DC and series motors.

◾With 2-axes servo motor applied to drive flyers for high speed and

precise coil winding.

◾With AC servo motor applied and the precision of angle changes can

be made up to 0.01°. Various wire hooking modes can be set at any angle within

360° per armature characteristics.

◾Depends on customer's demands, automatic cutting and cut off/hold

copper wire automatically by mechanisms are available.

◾Modular molds and dies design, it is able to make fast positioning,

and with high repetitive accuracy will reduce time required for die changes

tremendously.

◾6-stage tension control is made by the highly sensitive tension

controller and the electrical control system for perfect tension performance

during winding.

◾Based on Japanese PLC controller with 10" touch panel promptly

to display various operation statuses and running monitoring function.

◾For model TWM308A, it is able to equip with a robot arm and

conveyor, to meet function of fully automatic production.

◾It is able to equip with remote monitoring module to do remote

program monitoring safeguard.

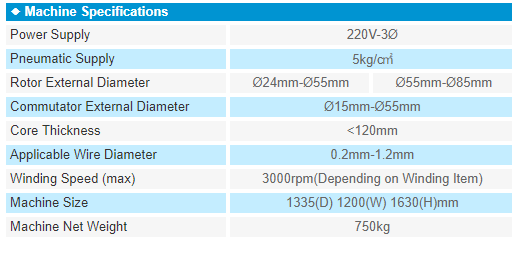

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice.