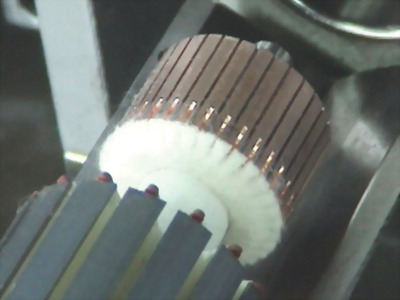

◾Applicable for automatic commutator slotting for a variety of carbon brush and series motors.

◾Preliminary positioning is conducted by mechanical pawl and the servo shifting system extend slotting application.

◾The adjustable gear replaces the traditional tooth belt for transmission to reduce errors of cutting precision resulted from flexibility of the belt.

◾Synchronous cutting of dual tools enhances cutting efficiency.

◾Modular molding design can be rapidly position and high repetition accuracy and result in reducing tooling changing time tremendously.

◾Independent servo feed unit can fine adjust cutting depth individually and easy for maintenance.

◾Feature of humanized operating interface, easy slot number setup and automatic error detection.

◾Optional robotic arm and conveyor belt achieves unmanned and fully automatic production line.

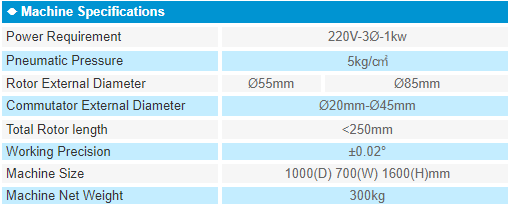

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice。