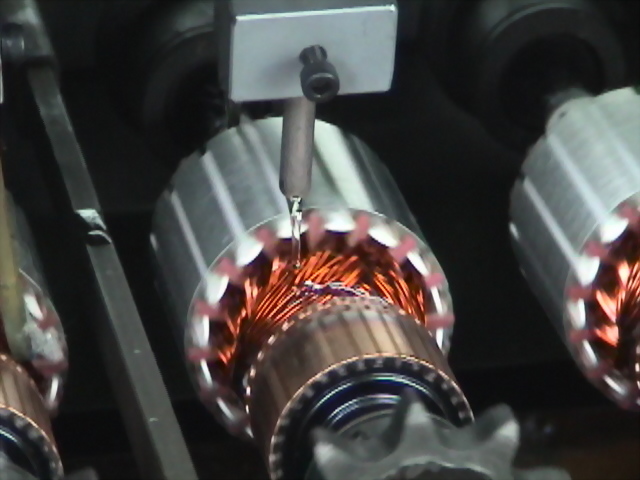

◆ 8-tube independent glue injection system. The dripping volume and dispensing configuration of each tube can be set separately according to the armature conditions.

◆ The automatic positioning and dispensing can accurately drip the varnish on the same area of each armature to achieve a unified standard.

◆ Automatically detect if incoming materials are available, and then start to continuous dispensing operations. Or intermittent dispensing operations for small amount of armatures to reduce the loss of varnish.

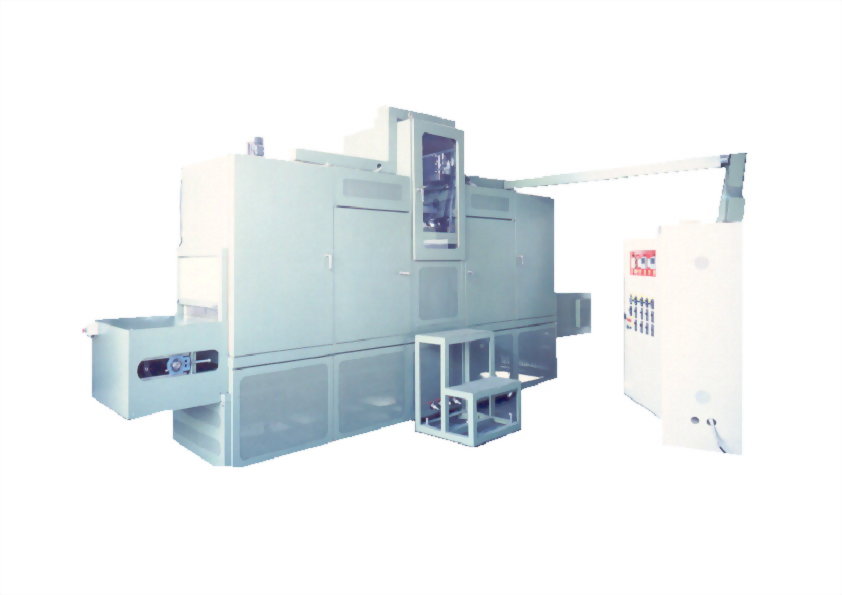

◆ Dripping area is isolated and has an independent ventilation system in order to avoid varnish smell spillage.

◆ In addition to the varnishing dripping system, this model can connect the ring neck glue automatic dripping system, therefore varnishing and ring neck glue dripping can be done one time. This can effectively reduce dripping time.

◆ Double shaft end ejecting mechanism, no need to replace the fixture and rotor runs smoothly without shaking. Prime quality on varnish absorbing and drying.

◆ Fixture adjustment adopts snap-type design without the use of tools. Quick fixture adjustment.

◆ Revolution and rotation are controlled independently. Armature transfer setting (revolution) and rotary speed can be set up according to the characteristics of the armature and varnish.

◆ Equipped with automatic transmission tension adjustment mechanism and automatic overload protection mechanism.

◆ Equipped with rotation speed compensation function. Rotation speed will not be affected by revolution.

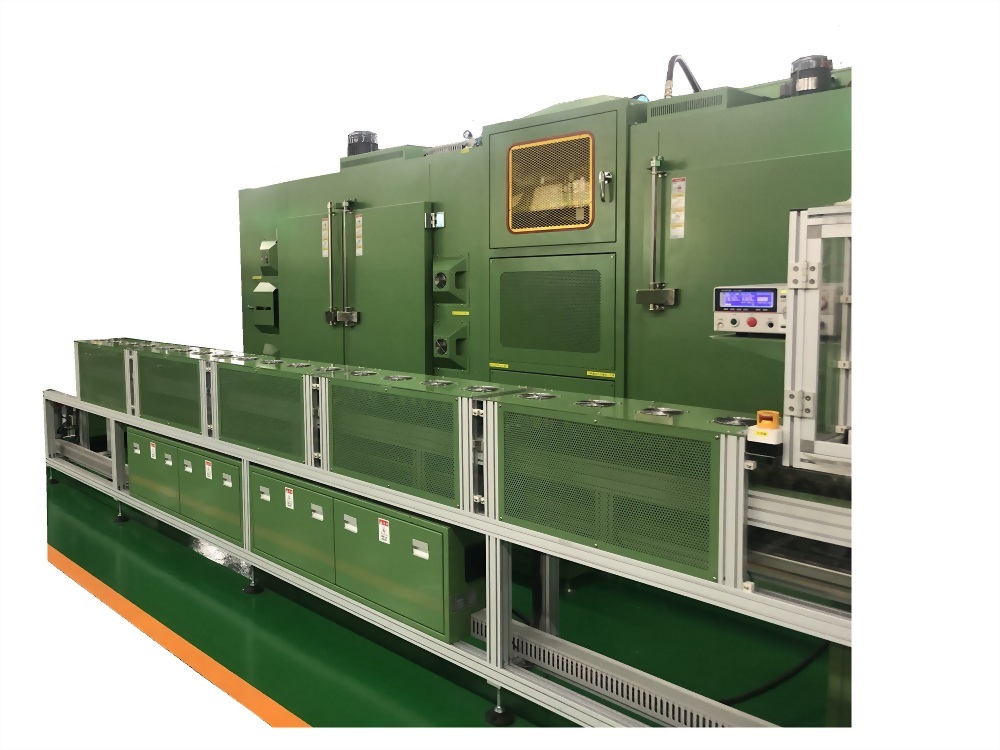

◆ Preheat zone and hardening zone is independently

controlled. Maximum temperature is 180℃

◆ Unique hot air circuit design greatly reduce hot

air outflow at the inlet and outlet which effectively improves the electric

heating efficiency.

◆ Adopts PID temperature control module + SSR

current control module to control the accuracy of the temperature in the

furnace±2%.

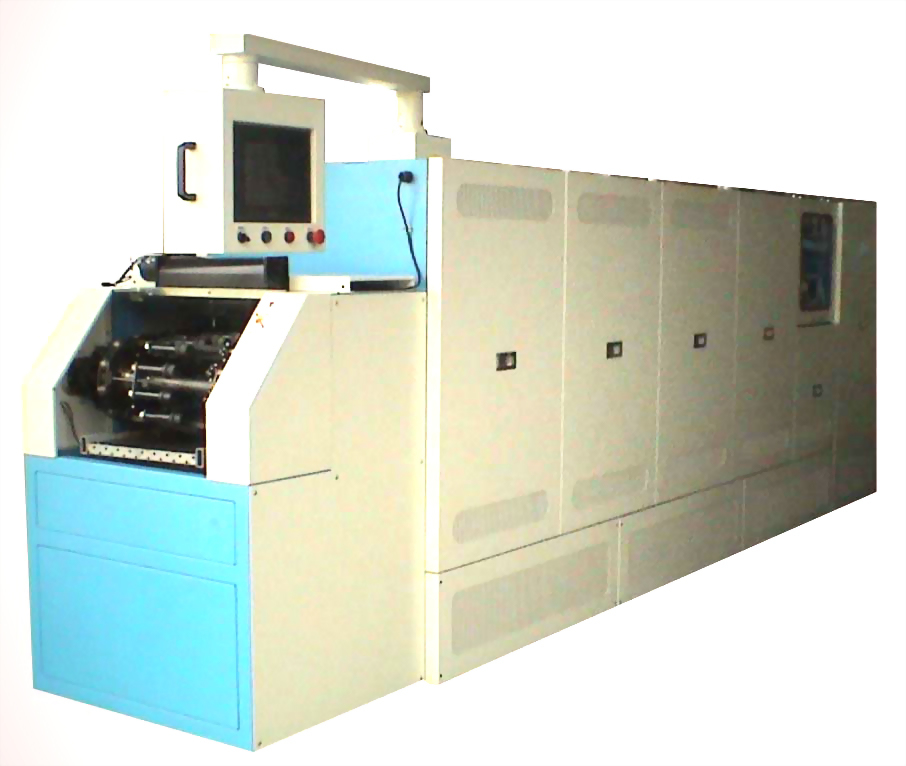

◆ The control system adopts Japanese PLC with 10”

touch screen interface which can display various operation information and

monitoring operation in real time.

◆ Humanized design with real-time switching on manual/automatic function, operation monitoring function, automatic reminder of maintenance function and automatic abnormal detect function …etc.

◆ It can store up to 100 sets of working parameter settings which allows user to access to various parameters more quickly when changing models. Saving tremendous time when changing models.

◆ Remote program monitoring and maintenance can be performed.

◆ This series of products can be tailored to different machine size, shapes and finishing product quantity. Moreover, manual glue dispenser is available to choose from.