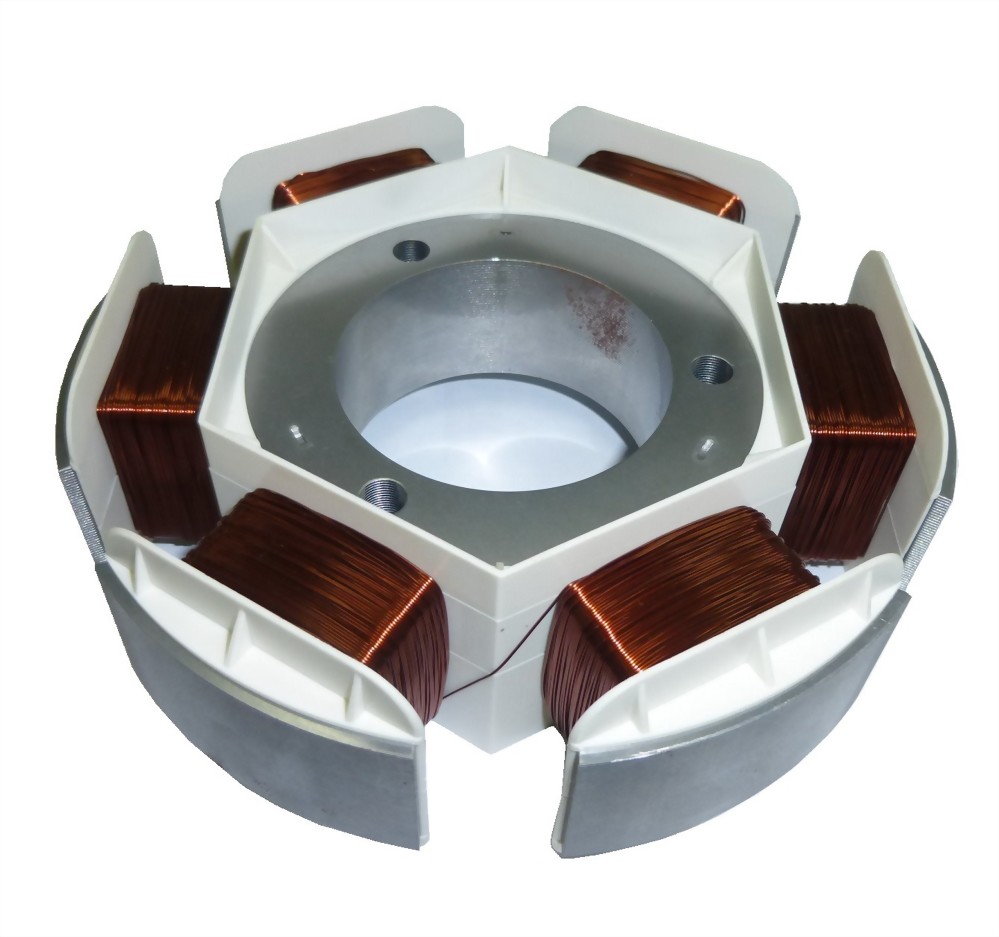

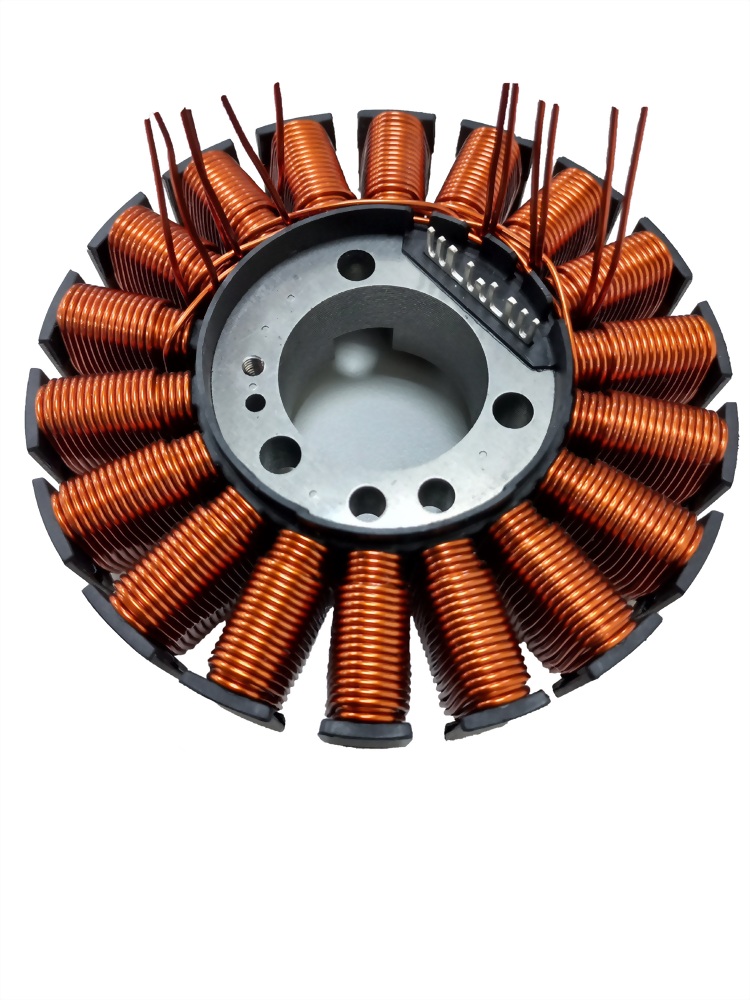

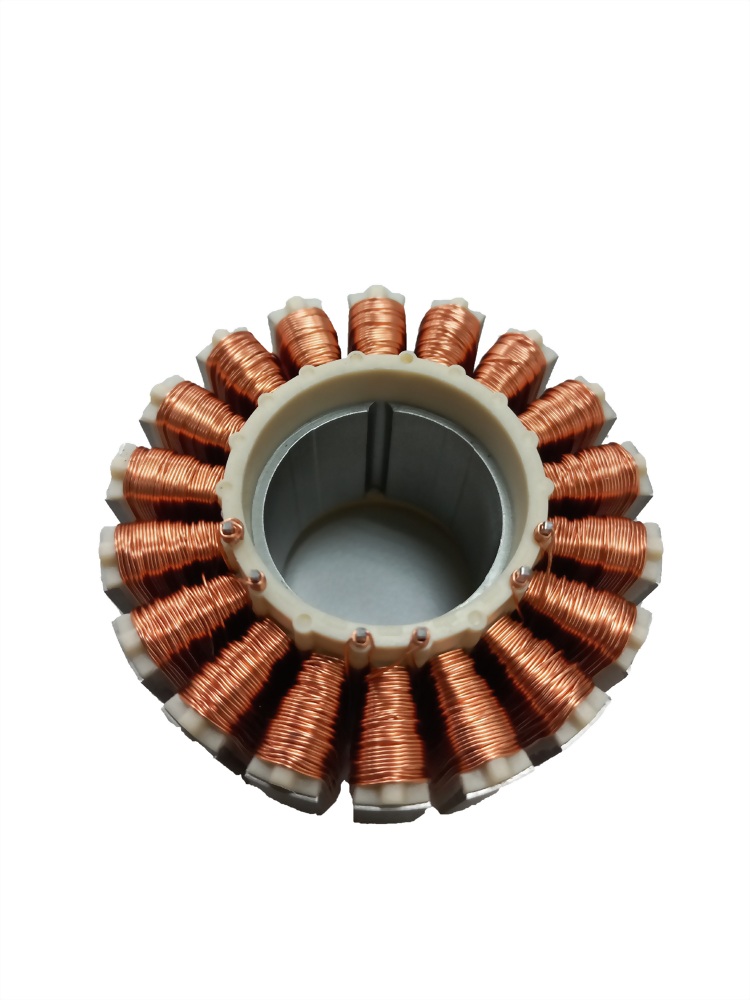

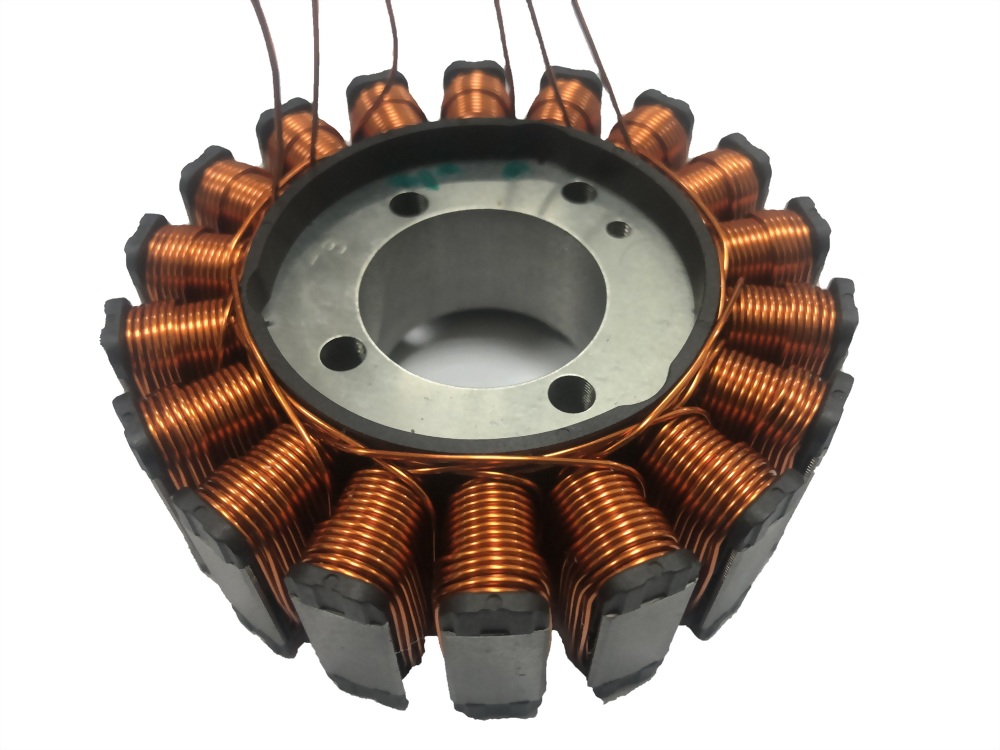

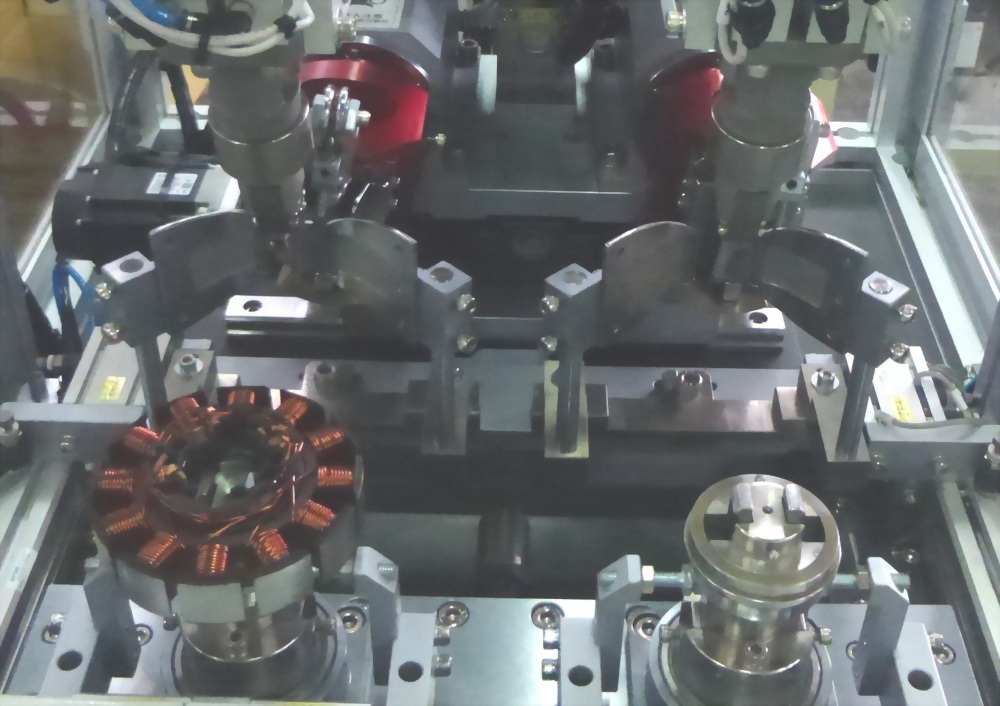

The TWM-929 is a high-performance automatic winding machine, expertly designed for the specific needs of BLDC (Brushless) out-slot stators. Leveraging Teamwork Automation's decades of expertise, this machine delivers a powerful combination of speed, precision, and stability for modern motor manufacturing.

Driven by precision servo motors, the TWM-929 ensures consistent, high-speed winding with exceptional stability, maximizing your production throughput and reducing labor costs. Its advanced control system allows for precise wire arrangement, neat and tight coils, and a high slot-fill rate, which directly enhances the final motor's efficiency and performance.

Your Partner in Automation

Teamwork Automation (FaTop Automation) provides more than just standard machines. We offer comprehensive, customized solutions, including integration into fully automated turnkey production lines. Contact our engineering team today to discuss your specific requirements and receive a customized technical proposal.

◾Applicable for all kind of In-slot brushless motor.

◾This series adopts multi-station configuration. Being able to set up the winding parameters and winding simultaneously which improve production efficiency.

◾Modular tooling design which allows prompt position and high repeatability. Greatly reduce tooling changing time and improves production efficiency.

◾This product can be connected with hand-wheel dynamic simulation system which enhancing the safety while operating and ease to operate.

◾Analog section tension output control which provide tension at each stage during stator winding and greatly improve product yield.

◾Equipped with automatic wire trimming mechanism. Copper wire will be cut and clamped automatically when winding is finished. This will be easier to take out the finish product.

◾The control system adopts Japanese PLC with 10” touch screen interface which can display various operation information and monitoring operation in real time.

◾This product can be assembled with remote monitoring module for remote program monitoring and maintenance.

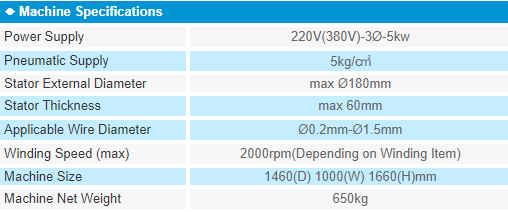

*Please contact TeamWork for requirements outside these specifications.

We reserve the right of technical modifications without notice。