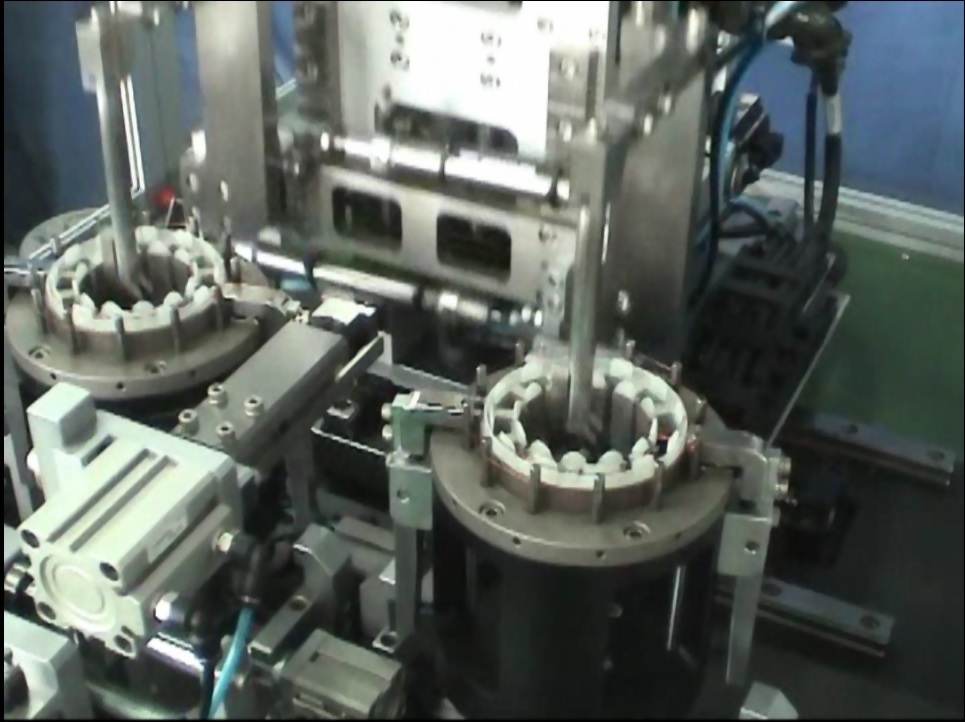

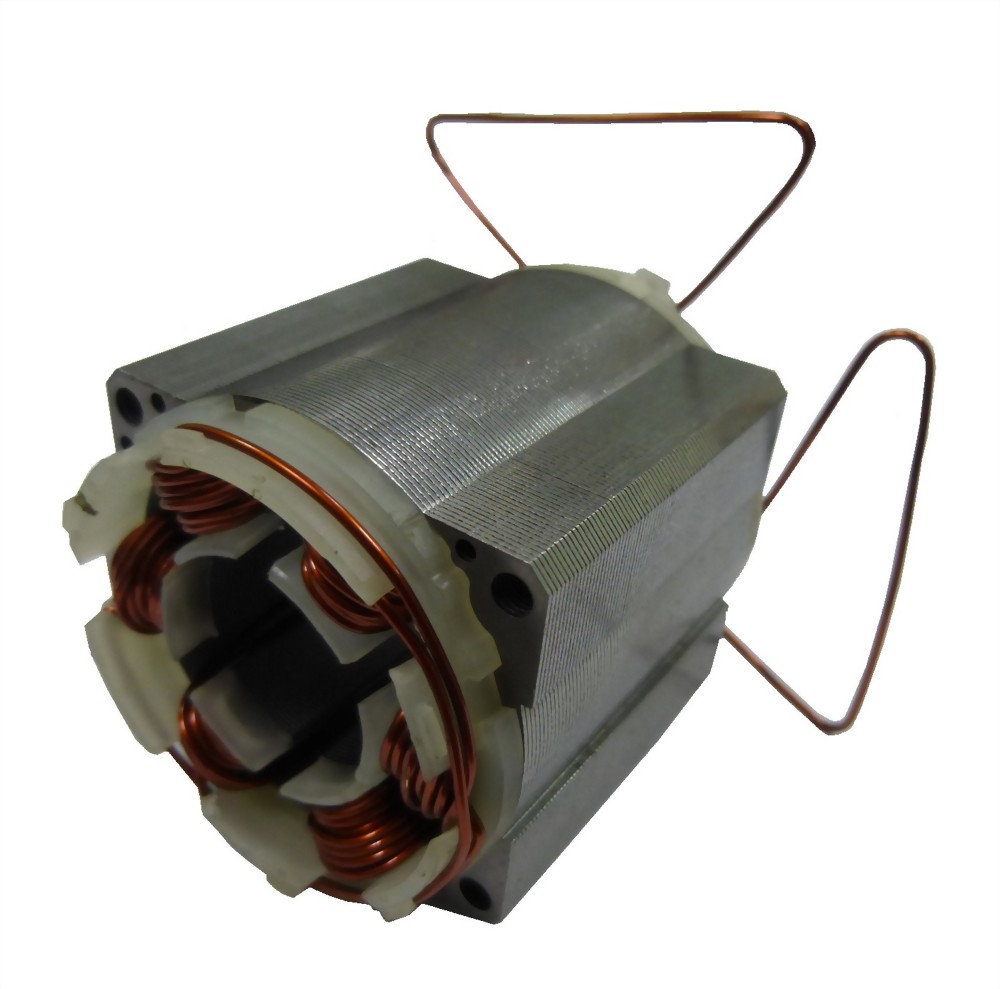

◾Applicable for automatic winding of in-slot brushless motors

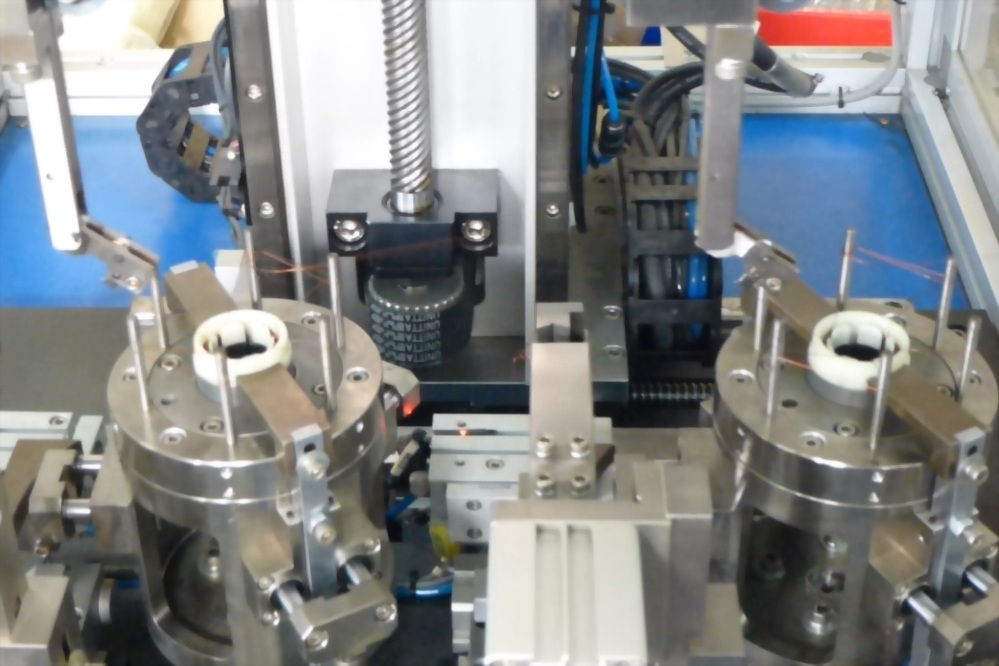

◾This product is adopting dual-axes independent control which is capable to set independent winding parameter, also synchronous to run winding for different specification of stators. This will increases the flexibility of this machine.

◾ Module molding design, prompt position repetitive is high. This is not only reduce the mold changing time, but also improve productitve.

◾ This product can be equipped with hand-wheel dynamic simulation system. This will largely improve operator’s safety and much more convenience to operating.

◾Patented copper wire nozzle up down automatic wire lacing system which greatly reduces post production time.

◾Implement share tooling design. The same set of tooling may be changed for different stacked heights to reduce mold development cost.

◾Guided action programming system improves the flexibility of equipment application and greatly increase the production capability.

◾The analog tension output control system provides tension for the stator on each coil winding stages and greatly improves the quality. Optional for servo tension output control provides more accurate tension control.

◾Equip with automatic wire cutting mechanism. When stator winding has finished, it is capable of cutting copper wire end automatically and clamp. This makes it easier for collecting finished product.

◾The control system adopts Japanese PLC with 10” touch screen interface which can display various operations information and monitoring operation in real time.

◾This product can be assembled with remote monitoring module for remote program monitoring and maintenance.